The development of carpet fabric printing began in the early days of the tufted carpet industry. This industry has made great progress since the early 1950, led by the United States. After more than half a century of development, there are basically three kinds of carpet printing equipment used by carpet printing manufacturers: ① flat screen printing machine; ② circular screen printing machine; ③ ink-jet printing machine controlled by microcomputer. The digital inkjet printing used by our company started in the 1970s, aiming to develop a non-contact printing system and apply digital technology to produce multi-color patterns. The technology achieved rapid development in the 1990s, completing the transformation from technical model to production application. 1999 Paris International Textile Machinery Exhibition, digital jet printing system gained wide attention and application in the industry.

Screen printing is not quite suitable for a small batch of full pile carpet due to the limitation of the pattern by flower back and the limitation of net making. Jet printing technology, on the other hand, can fully meet the needs of the market.

First: short process and fast delivery, can meet the characteristics of small-batch, multi-color, and fast delivery requirements.

Second: inkjet printing technology can print up to 16 colors, which can meet the individual use market for wall tapestry patterns.

Third: inkjet printing has high efficiency it can meet the high volume orders and short delivery time.

Fourth: inkjet printing carpet color and the color transition is more natural and delicate.

With the continuous and rapid development of the domestic economy and the improvement of people's living standards, the amount of commercial and residential carpets will appear in parallel. Carpets into the family is imminent, due to the cultural differences and personalization of customers is also becoming more and more obvious, resulting in smaller and smaller batch, more and more colors; the pace of life accelerates, requiring shorter and shorter delivery time, family decoration into the era of personalization, etc. To us, inkjet printing is an opportunity and challenge.

Within two pixels of a uniform miscellaneous dot pattern, the pattern is easy to misalignment, and deform.

Vertical stripes within four pixels, solenoid valve frequently off and on, easy to fail, damage, it is recommended to change to horizontal stripes (more than two pixels).

Typesetting a cycle of more than 20 meters corridor blanket, file memory is too large, easy to a computer crash, failure, file loss, etc.

Two adjacent color contrast is too large, easy to produce bleeding and splash color.

Printed full pavement carpet is not suitable for large areas plain color, it is recommended that available blank dye. When splicing in the hall, it is recommended that both sides of the pattern should preferably use plain color or miscellaneous dots to avoid the phenomenon of not being able to cause splicing.

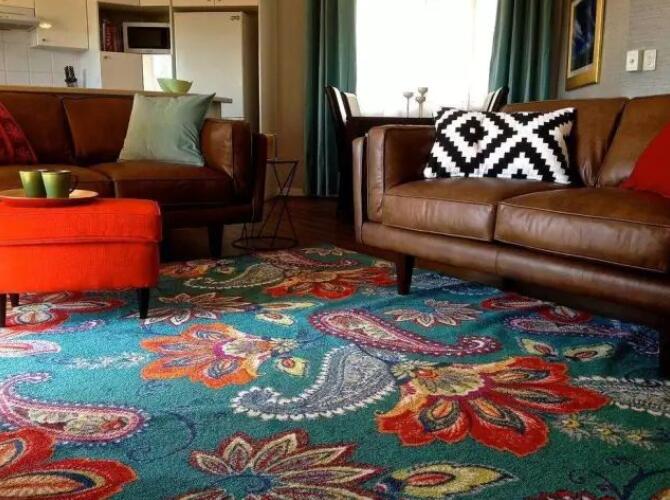

Direct Factory Contemporary Living Room Carpets And Rugs

Previous: Tips for Choosing the Carpet

Previous: Tips for Choosing the Carpet